Specialists in excellence

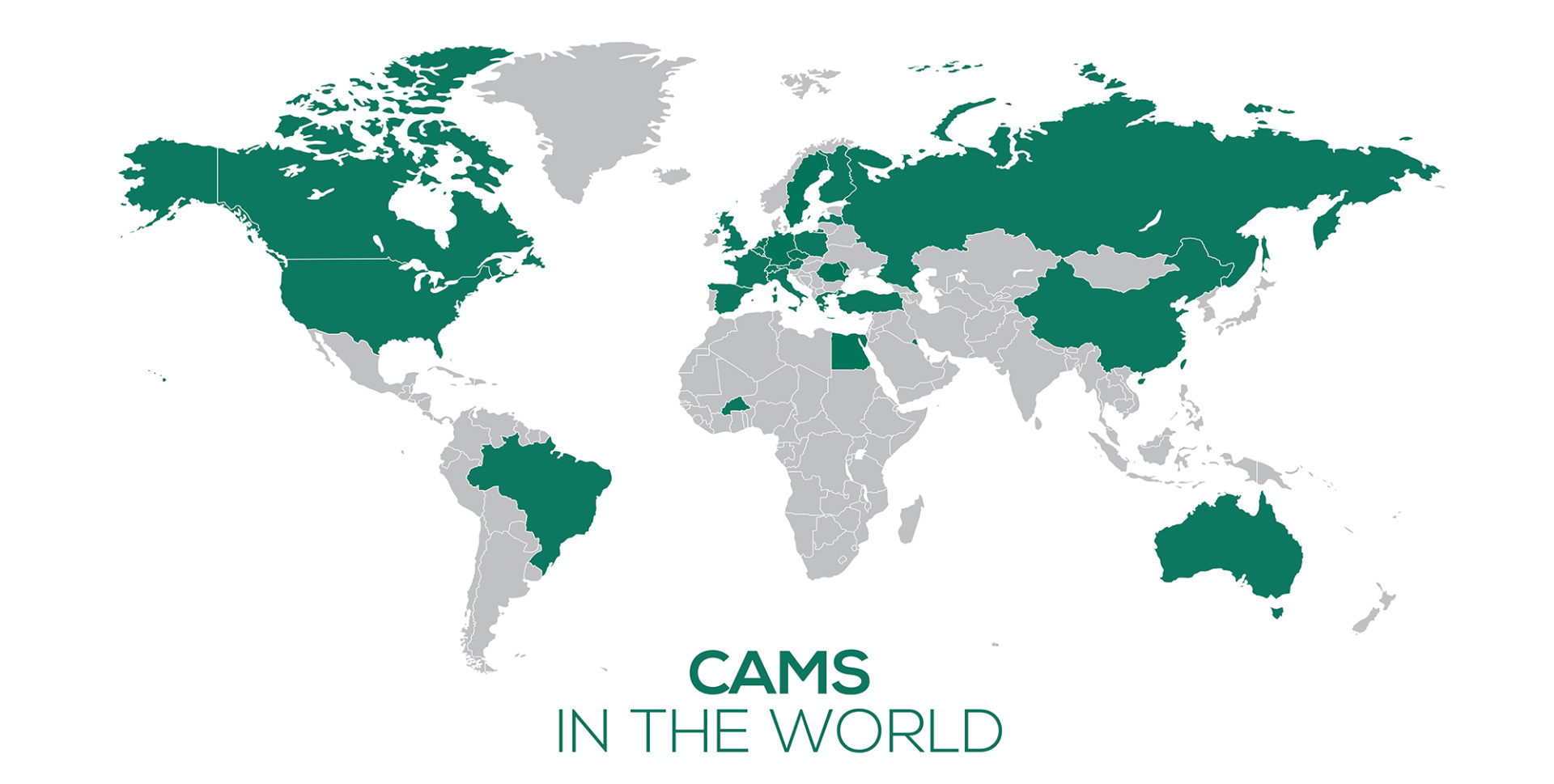

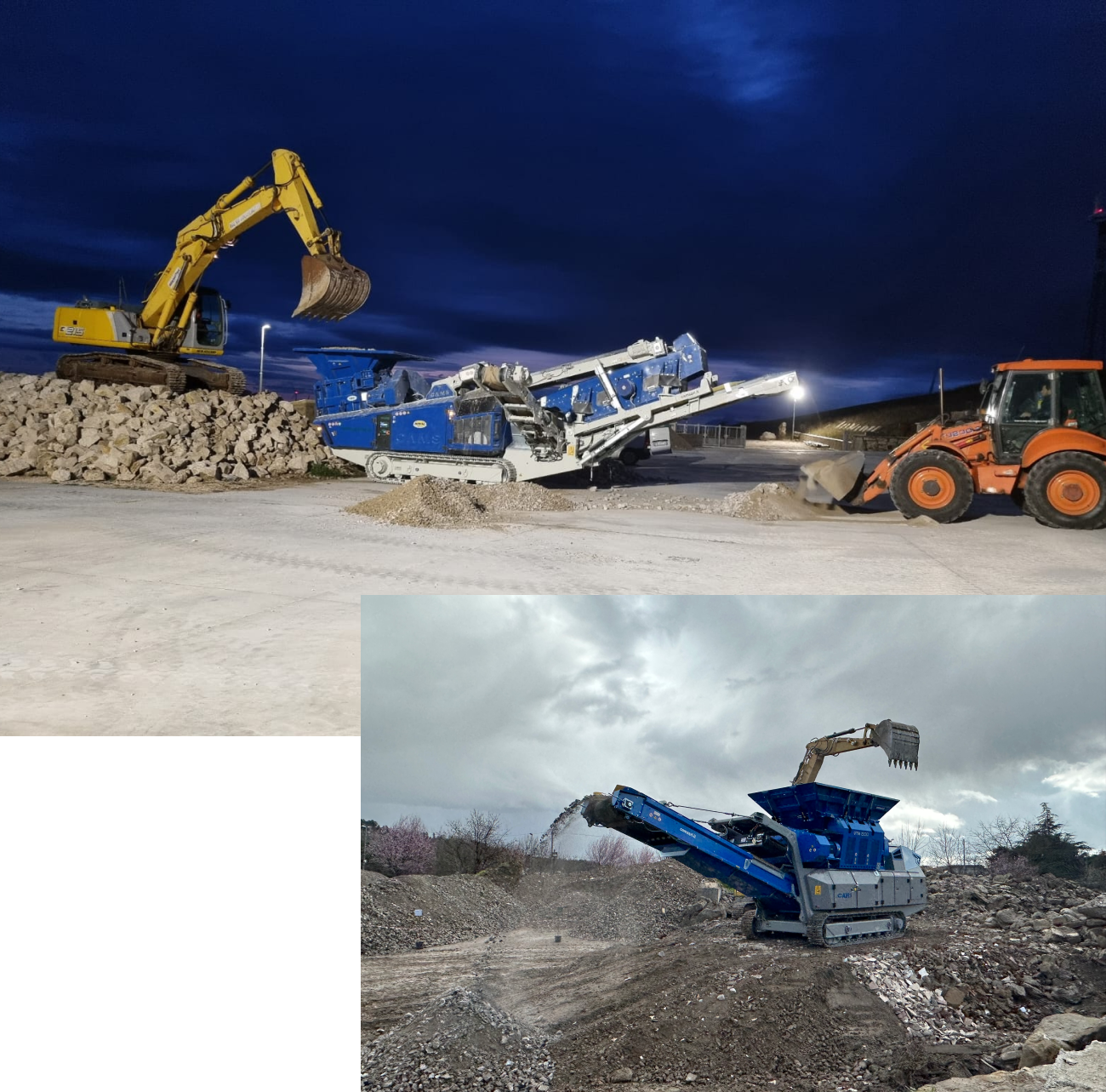

Leader in the design and manufacture of fixed and mobile crushing, screening and shredding plants

Cams produces crushing, shredding and screening plants entirely managing all the phases of the production process, from the executive design to the development and the construction of the machines. It carefully monitors every production step, constantly checking the quality of materials and manufacturing processes.

Specialists in excellence

Cams produces crushing, shredding and screening plants entirely managing all the phases of the production process, from the executive design to the development and the construction of the machines. It carefully monitors every production step, constantly checking the quality of materials and manufacturing processes.

Featured news

October 15, 2021

October 15, 2021

Categories

See you at the fair! Let’s start up again together: present in Saie Bari, Sim Lille, Smopyc Zaragoza and Asphaltica Verona!

November 17, 2020

November 17, 2020

Categories

Read the article about us in “Strade & Autostrade” Magazine

November 17, 2020

November 17, 2020

Categories

In compliance with the Security Protocol of March 14, 2020 and Legislative Decree no. 81/2008, CAMS srl has adopted the following protocol for the prevention of contagion […]

CUSTOMIZED PLANTS

REVIEW AND MAINTENANCE

REMOTE CONTROL

HYBRID/ELECTRIC TECHNOLOGY

MEDIA LIBRARY

SPARE PARTS SERVICE

CONSULTING AND INSPECTION ON SITE

RENT

Our experience at your disposal

Experience acquired over many years of direct contact with customers has taught us how important it is to respond quickly to all enquiries.